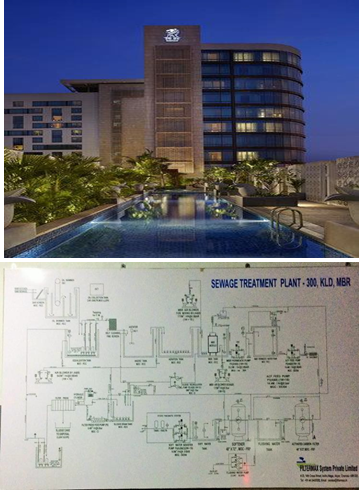

DAIMLER, CHENNAI

500 KLD SIDE STREAM MBR BASED SEWAGE TREATMENT PLANT

The Background

Daimler India Commercial Vehicles is situated in Chennai City , Tamil Nadu. Daimler wanted to install a Sewage Treatment Plant with recycle system at their manufacturing facility using latest technologies. Daimler selected M/s Filtermax to execute the project as Filtermax being Pentair’s distributor and master sub contractor.

The Facility

Daimler India Commercial Vehicles produces trucks and buses specially designed for the Indian market and for its export markets in Asia, Africa and South America. DICV’s state of the art Oragadam Plant near Chennai is the only Daimler facility producing three brands of commercial vehicles.

In line with group’s objective to recycle the effluent generated from their Plant, Daimler decided to implement a STP and recycle system at this property.

The intend is to recover maximum treated water from the effluent generated and thus achieve the objectives.

The Solution

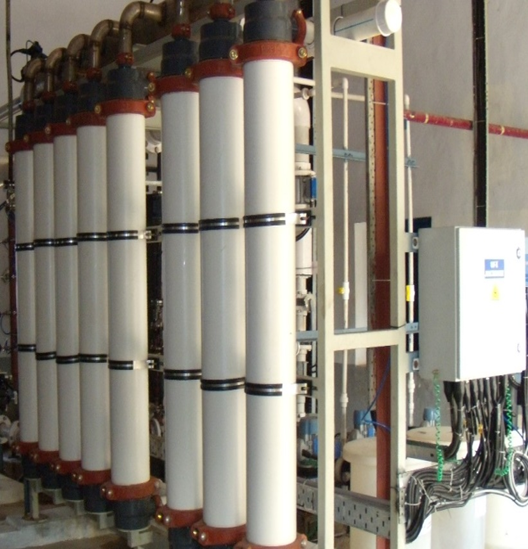

Filtermax in association with Pentair designed and executed the scheme. System erected and started commissioning by Nov 2014 and handed over successfully.

Wastewater rich in BOD, COD, oil & grease etc. The space was also a constrain. Considering these limitations MBR based treated scheme was opted so as to achieve ease of operation and saving space.

The system based on latest side stream MBR technology was neatly designed and executed by Pentair and FILTERMAX. The capacity of the system is 500 KLD.The system was commissioned in Nov 2014 and performing well since commissioning.

The biological treatment scheme comprises a Bar screen, oil skimmer, equalization tank, fine screen, anoxic zone , diffused aeration and MBR. The post treatment involve Activated Carbon Filtration and Ion Exchange Softening. The treated water recycled for various applications such as flushing, CT make up etc.

The biological treatment scheme comprises a Bar screen, oil skimmer, equalization tank, fine screen, anoxic zone , diffused aeration and MBR. The post treatment involve Activated Carbon Filtration and Ion Exchange Softening. The treated water recycled for various applications such as flushing, CT make up etc.